With this type of packaging, the need to purchase disposable packaging – which will need to be recycled or routed to a landfill – is reduced or eliminated entirely.

Returnable packaging solutions have been designed for reuse in manufacturing and distribution systems. A regular disposal process for materials needs to be incorporated into the lifecycle of the manufacturing and packaging process. These types of products are generally viewed as single-use packaging solutions that will be recycled or thrown out after the vehicle part reaches its final destination. When it comes to shipping automotive parts, there are two main types of packaging used by manufacturers: expendable and returnable.Įxpendable packaging is disposable, and it is made out of materials like paper, plywood, wood, or corrugated cardboard. At Nefab, we help businesses to create customized vehicle part packaging and shipping solutions in order to protect products while minimizing costs. Without the right packaging solutions, vehicle parts could be damaged during shipment, and transport costs could get out of control. The highly globalized vehicle industry takes advantage of advanced manufacturing, development, and logistics flows, but its complexity requires a variety of packaging materials. Delivering Safe and Cost Effective Packaging Solutions

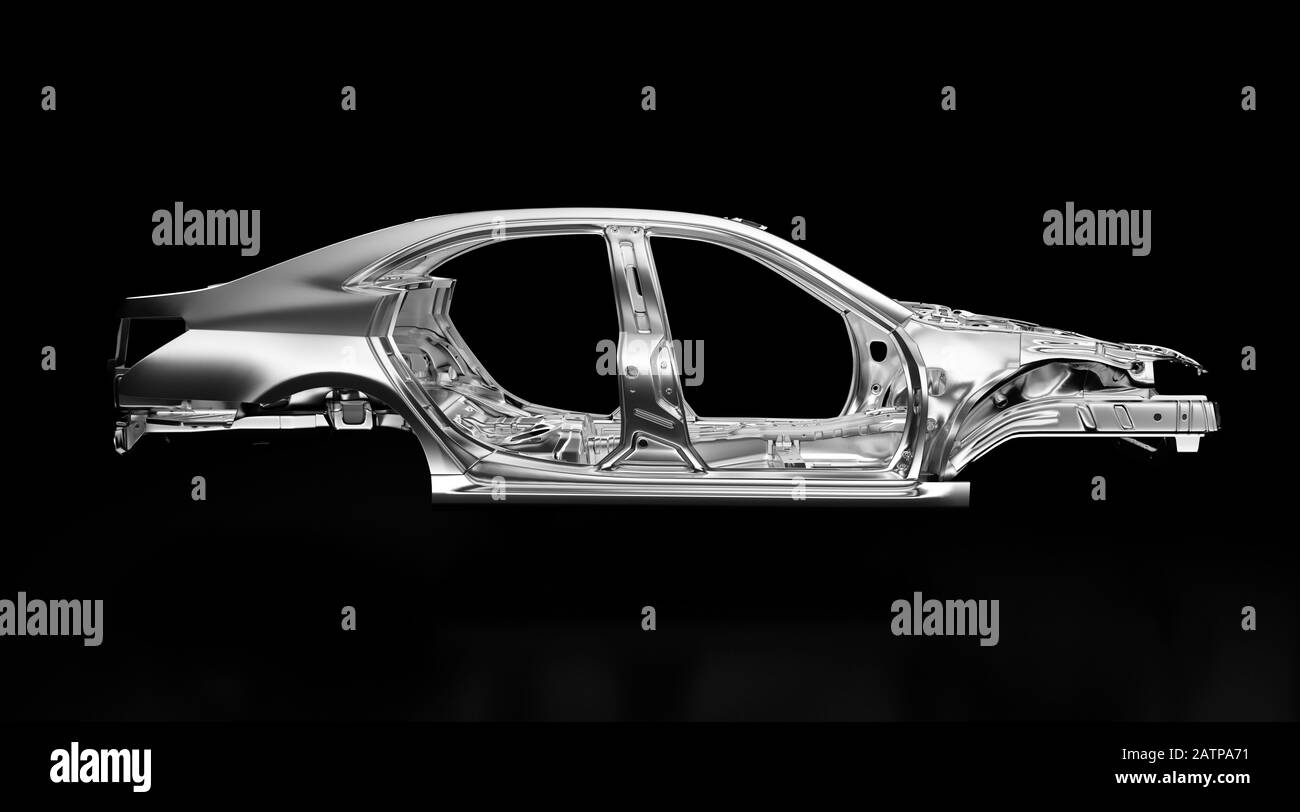

Therefore, it should come as no surprise that the vehicle industry accounts for over 40% of all the industrial and transport packaging that is needed worldwide. From the engine to small mechanical elements and decorative interior items, the production of a vehicle requires thousands of different components. In the automotive industry, it is crucial to have packaging solutions that deliver ultimate protection for high value goods and parts.

0 kommentar(er)

0 kommentar(er)